Weight reduction is a challenge in all industries. Weight reduction leads to either faster movement or less energy consumption and thus to a better environment. There is a strong push from the governments across Europe to further reduce weight. However most of the time, the primary limiting factor on weight reduction are the available materials.

When parts are exposed to friction and wear, generally only heavy materials remain usable. Modern composite materials generally have very low hardness, since they are built using a combination of a fiber material with a matrix material that is essentially just a plastic.

We combine the wear resistance of ceramics and the light weight of carbon fiber into a rigid, durable, ultra-strong and light-weight material. By applying a ceramic coating on carbon fiber, we are able to outperform any existing material. Our product is up to 4 times lighter than steel and 100 times more durable compared to carbon fiber. Ultimately, our material aims to helps manufacturers scale bigger and faster.

CeraCarbon sprockets combine the hardness of ceramics, the lubricating properties of PTFE and the high strength to weight of carbon fiber to make some of the most performant motorcycle sprockets in the world!

One of the main advantages in USD forks are fixed tubes of larger diameter than the sliding tubes and the very long path of the sliding tubes through the fixed tube. The USD system serves to raise torsional rigidity and at the same time cannot twist in the fork bridge.

However, the unsprung masses in a USD fork are not smaller than in a conventional fork. The sliding tubes running inside the USD system are still made of heavy steel which makes the USD system not lighter than the old conventional forks

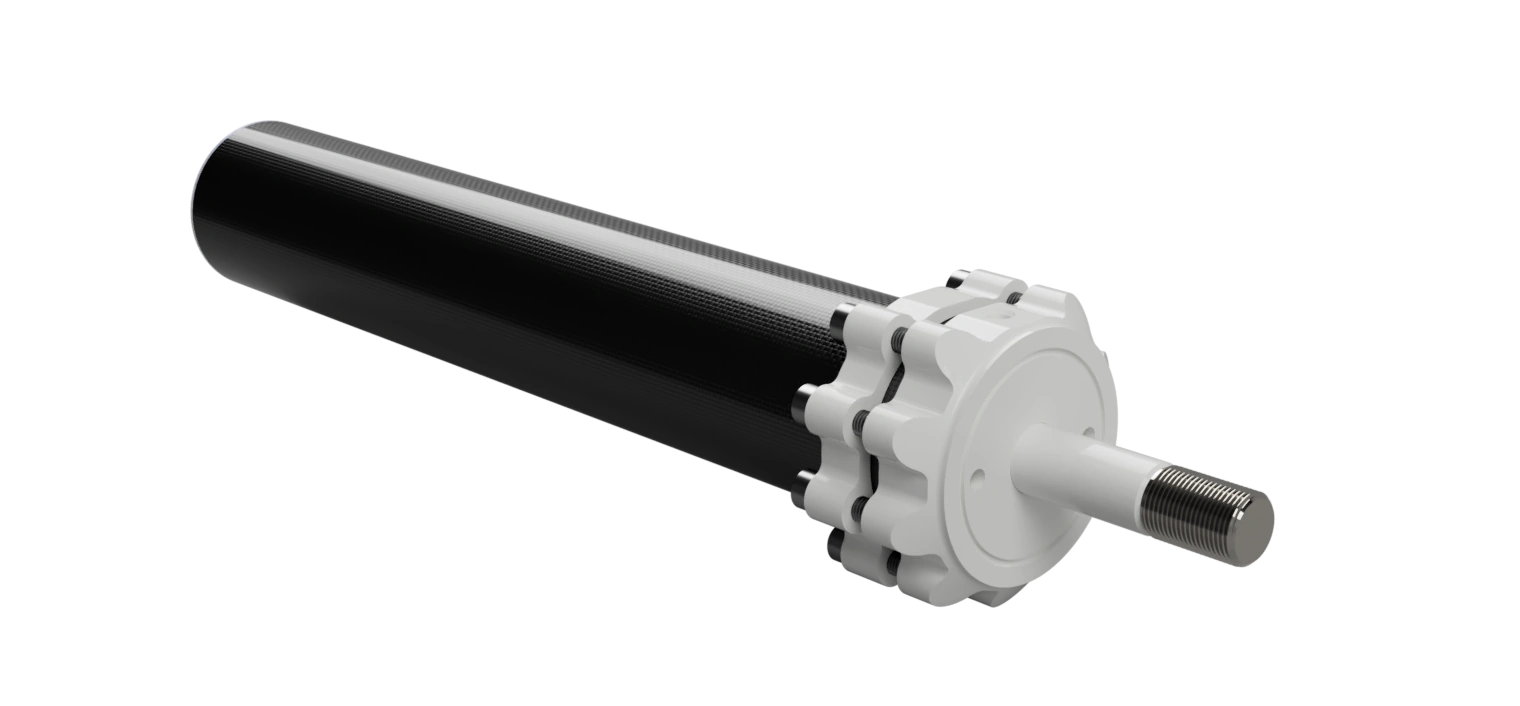

Our Ultra light hydraulic cylinders with the our special developed Ceramic Liner are built to work in the toughest and most challenging conditions.

The first designs are done in close connection with our customers and has allowed us to create and expand our portfolio with Single acting hydraulic cylinders that meet the harsh marine environment. The combination of different materials, Carbon, Titanium and Ceramics results in a very special product.

Current designs are still custom made and we will accept any challenge up to 3.00m in length and 300mm diameter for the moment. The combination of Carbon and Ceramics will result is ultra light and strong solutions.